Project

Development Technology Final goal

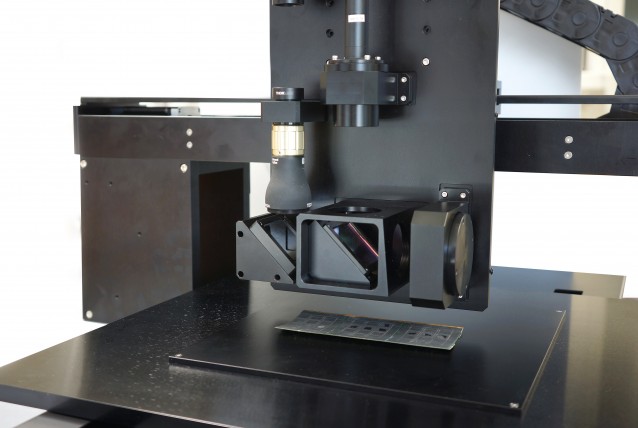

1) Development of 3D inspection optical module

2) Development of 3D glass curvature and thickness inspection technology

3) 2D quality inspection technology development

1) Development of 3D inspection optical module

2) Development of 3D glass curvature and thickness inspection technology

3) 2D quality inspection technology development

Project Summary

As smartphones, wearable IoT devices are developed and automotive displays are diversified, flat and curved coverglass demand is increasing. But 3D coverglass makers, Biel Crystal and Lens One in China with now 80% market share worldwide are conducting sample inspections without 3D inspection equipment.

Business Model

As the mobile and wearable market grows the need for glass inspection is also growing. Currently, the glass market is being tested by people's eyes.

There is no technology or equipment to replace the human eye, so the need for 3D inspection is getting bigger.

Humen Co., Ltd. provides a solution that can inspect all glass inspection in 2D and 3D by using proprietary technology.

There is no technology or equipment to replace the human eye, so the need for 3D inspection is getting bigger.

Humen Co., Ltd. provides a solution that can inspect all glass inspection in 2D and 3D by using proprietary technology.

Main Achievements

1. Developed 3D inspection optical module capable of large-area inspection (under verification)

2. 3D Glass Curvature Calculation Thickness Checking Algorithm (Improving)

3. Algorithm for 2D quality inspection (scratch, foreign body, crack) (development completed)

4. Intellectual property rights (patent, utility model, etc.): 1 case

* Future Plans

In the first year, development of 2D and 3D inspection technology is completed.

In the second year, we will build inspection equipments, integrate inspection technology, and apply 3D cover glass inspection as 2D / 3D inline inspection.

2. 3D Glass Curvature Calculation Thickness Checking Algorithm (Improving)

3. Algorithm for 2D quality inspection (scratch, foreign body, crack) (development completed)

4. Intellectual property rights (patent, utility model, etc.): 1 case

* Future Plans

In the first year, development of 2D and 3D inspection technology is completed.

In the second year, we will build inspection equipments, integrate inspection technology, and apply 3D cover glass inspection as 2D / 3D inline inspection.

Date of EstablishmentDecember 9, 2016

AcceleratorKorea Business Angels Association

StageElectrical/Electronic

Date of TIPS Selection2016.12.01